Views: 8 Author: Monica Publish Time: 2026-01-05 Origin: Site

ASME B16.11 is a production standard for forged high-pressure fittings.

ASME B16.11 is a standard published by the American Society of Mechanical Engineers that covers forged fittings, specifically socket-welding and threaded types. This standard establishes requirements for ratings, dimensions, tolerances, marking, and material specifications for these types of forged fittings.

The standard is the forged steel fittings and includes different pressure classes such as Class 2000, 3000, 6000, and 9000 fittings.

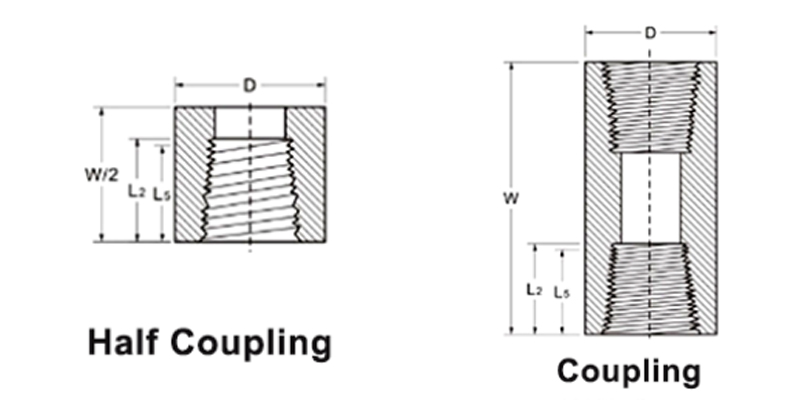

ASME B16.11 forged steel couplings, including full couplings, half couplings, and reducing couplings, are available with socket-weld or threaded ends. Couplings are used to join pipes or connect to other components in high-pressure systems.

Full couplings connect two pipes end-to-end, while half couplings connect one pipe end to a vessel or plate. Reducing couplings join pipes of different sizes.

Dimensions are in inches or millimeters, with tolerances for bore, wall thickness, and length.

ASME B16 11 Coupling and Half Coupling Dimension

Nominal size | End-to-end | Outside diameter | Length of thread | |||

DN | NPS | W | D | L5min | L2min | |

3000 & 6000 | 3000 | 3000 | ||||

6 | 1/8 | 32 | 16 | 22 | 6.4 | 6.7 |

8 | 1/4 | 35 | 19 | 25 | 8.1 | 10.2 |

10 | 3/8 | 38 | 22 | 32 | 9.1 | 10.4 |

15 | 1/2 | 48 | 28 | 38 | 10.9 | 13.6 |

20 | 3/4 | 51 | 35 | 44 | 12.7 | 13.9 |

25 | 1 | 60 | 44 | 57 | 14.7 | 17.3 |

32 | 11/4 | 67 | 57 | 64 | 17.0 | 18.0 |

40 | 11/2 | 79 | 64 | 76 | 17.8 | 18.4 |

50 | 2 | 86 | 76 | 92 | 19.0 | 19.2 |

65 | 21/2 | 92 | 92 | 108 | 23.6 | 28.9 |

80 | 3 | 108 | 108 | 127 | 25.9 | 30.5 |

100 | 4 | 121 | 140 | 159 | 27.7 | 33.0 |

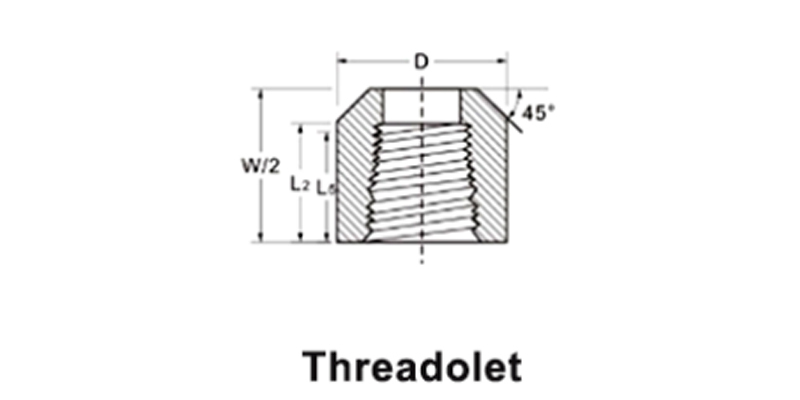

ASME B16.11 Threadolet, also known as threaded branch outlet or Thredolet, is a forged steel branch connection fitting that provides a threaded outlet from a larger run pipe.

It is welded to the run pipe and features a threaded end for the branch connection, making it suitable for high-pressure piping systems where a reinforced branch is needed without full penetration welding on the branch side.

ASME B16.11 Threadolet Dimension

Nominal size | End-to-end | Outside diameter | Length of thread | |||

DN | NPS | W | D | L5min | L2min | |

3000 & 6000 | 3000 | 3000 | ||||

6 | 1/8 | 32 | 16 | 22 | 6.4 | 6.7 |

8 | 1/4 | 35 | 19 | 25 | 8.1 | 10.2 |

10 | 3/8 | 38 | 22 | 32 | 9.1 | 10.4 |

15 | 1/2 | 48 | 28 | 38 | 10.9 | 13.6 |

20 | 3/4 | 51 | 35 | 44 | 12.7 | 13.9 |

25 | 1 | 60 | 44 | 57 | 14.7 | 17.3 |

32 | 11/4 | 67 | 57 | 64 | 17.0 | 18.0 |

40 | 11/2 | 79 | 64 | 76 | 17.8 | 18.4 |

50 | 2 | 86 | 76 | 92 | 19.0 | 19.2 |

65 | 21/2 | 92 | 92 | 108 | 23.6 | 28.9 |

80 | 3 | 108 | 108 | 127 | 25.9 | 30.5 |

100 | 4 | 121 | 140 | 159 | 27.7 | 33.0 |

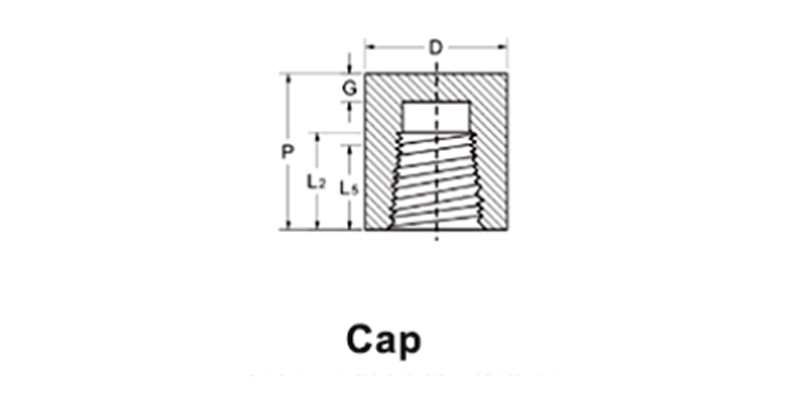

ASME B16.11 caps are forged steel pipe fittings designed to close off the end of a piping system, providing essential pressure sealing capabilities. These caps fall under the ASME B16.11 standard, which covers specifications for forged steel fittings, including both socket weld and threaded types.

For threaded caps, the size range typically spans from 1/8" NB to 4" NB, with pressure classes available in 2000 LBS, 3000 LBS, and 6000 LBS. Socket weld caps are also manufactured according to this standard and are commonly used in small-size piping systems up to 4 inches in diameter.

ASME B16.11 Cap Dimension

Nominal size | End-to-end | Outside diameter | End wall | Length of thread | |||||

DN | NPS | P | D | G | L5min | L2min | |||

3000 | 6000 | 3000 | 3000 | 3000 | 3000 | ||||

6 | 1/8 | 19 | — | 16 | 22 | 4.8 | — | 6.4 | 6.7 |

8 | 1/4 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

10 | 3/8 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

15 | 1/2 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

20 | 3/4 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

25 | 1 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

32 | 11/4 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

40 | 11/2 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

50 | 2 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

65 | 21/2 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

80 | 3 | 65 | 68 | 108 | 127 | 19.0 | 22.4 | 25.9 | 30.5 |

100 | 4 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33.0 |

ASME B16.11 Class 3000 refers to forged steel fittings with a 3000 PSI pressure rating classification.

For ASME B16.11 fittings, the pressure classes are organized as follows:

Socket Weld Fittings are available in 3000 LBS, 6000 LBS, and 9000 LBS pressure classes.

Threaded fittings are available in 2000 lb, 3000 lb, and 6000 lb pressure classes.

Class 3000 (3000 lb) is the most commonly used pressure class for socket weld fittings. These Class 3000 socket weld fittings are designed for high-pressure applications and are commonly used in systems such as heat exchangers, boilers, and power plants.

However, ASME B16.11 Class 3000 Forged Steel Fittings are generally considered suitable for medium-pressure applications when compared to the higher-pressure classes.

ASME B16.11 states that a fitting's pressure rating is equal to the burst pressure of the matching seamless pipe.

Class 3000 Socket Weld (SW) = Rated the same as Schedule 80 pipe.

Class 3000 Threaded (NPT) = Rated the same as Schedule 160 pipe.

Note: Because Schedule 160 pipe is thicker than Schedule 80, a Class 3000 Threaded fitting is actually much stronger than a Class 3000 Socket Weld fitting.

What is the difference between ASME B16.9 and B16.11?

The primary difference is connection type and size range: B16.9 is for large-bore butt-weld fittings, while B16.11 is for small-bore forged threaded and socket-weld fittings.

ASME B16.9 covers wrought factory-made butt-welding fittings typically used for larger pipes. These are welded edge-to-edge with the pipe. In contrast, ASME B16.11 covers forged fittings that are either threaded or socket-welded, designed for smaller diameters.

While B16.9 fittings are usually made from pipe or plate, B16.11 fittings are machined from solid forged blocks, making them more robust for high-pressure small-line applications.

What is ASME B16.11 used for?

ASME B16.11 is used to provide high-pressure, leak-proof connections for small-diameter piping systems in industrial environments.

These fittings are essential for "branch" lines, instrumentation, and utility piping where pipes are 4 inches or smaller. Because they are forged, they can handle extreme pressures (Classes 2000, 3000, 6000, and 9000). Common components include elbows, tees, crosses, couplings, and unions.

They are widely used in oil refineries, chemical plants, and power generation facilities where reliability in confined spaces is a priority.

When to use ASME B16.11?

Use ASME B16.11 when you are working with small-bore piping (4" and under) that requires high structural integrity or frequent maintenance access.

Specifically, you should choose B16.11 in the following scenarios:

Space Constraints: Socket-weld and threaded fittings are more compact than butt-weld or flanged connections, making them ideal for tight areas.

Small Diameters: It is the industry standard for pipes between 1/8" and 2".

High Pressure: When the system pressure is too high for standard cast iron or ductile iron fittings.

Ease of Assembly: Threaded fittings (B16.11) allow for assembly without welding, which is useful in explosive environments or for parts that need periodic replacement.