| Availability: | |

|---|---|

Hastelloy X (UNS N06002) is a nickel-chromium-iron-molybdenum superalloy designed for extreme high-temperature and corrosive environments. Developed by Haynes International, it combines oxidation resistance, creep strength, and fabricability for applications exceeding 1,000°C (1,832°F).

Grade | C≤ | Mn≤ | P≤ | S≤ | Si≤ | Cr | Mo | Fe | Co≤ | Ni | W |

Hastelloy X | 0.05-0.15 | 1.0 | 0.04 | 0.03 | 1.0 | 20.5-23.0 | 8.0-10.0 | 17.0-20.0 | 0.5-2.5 | Remain | 0.2-1.0 |

Properties | Value |

Density (g/cm3) | 8.28 |

Melting point (℃) | 1295, 1381 |

Thermal conductivity ( λ (W/m*℃) ) | 13.38 (100℃) |

Specific heat capacity (J/kg*℃) | 372.6 |

Elastic modulus (GPa) | 199 |

Resistivity (μΩ*m) | 1.18 |

Linear expansion coefficient (a/10-6 ℃-1) | 12.1 (20-100℃) |

Mechanical properties | Tensile, min, ksi[MPa] | Yield, min, ksi[MPa] | Elongation, %(min) |

Hastelloy X | 95[655] | 32[240] | 35 |

STANDARD | WERKSTOFF NR. | UNS |

Hastelloy X | 2.4665 | N06002 |

Hastelloy X possesses an exceptional combination of oxidation resistance, formability and high temperature strength.

It has also been found to be exceptionally resistant to stress-corrosion cracking.

Alloy X exhibits good ductility after prolonged exposure at temperatures of 1200, 1400, 1600 °F for 16,000 hours.

It has excellent formability and welding characteristics.

Hastelloy X can be forged and, because of its good ductility, can be cold-worked.

It can be welded by both manual and automatic welding methods including shielded metal-arc (coated electrodes), gas tungsten-arc (TIG), and gas metal-arc (MIG). Alloy X can also be resistance-welded.

Product Name | Standard | Show |

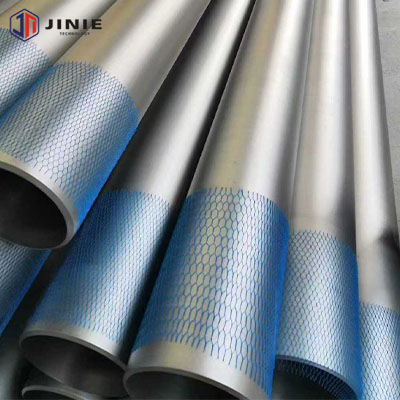

Pipe/Tube | AMS 5587 AMS 5588 ASTM B619 ASTM B622 |  |

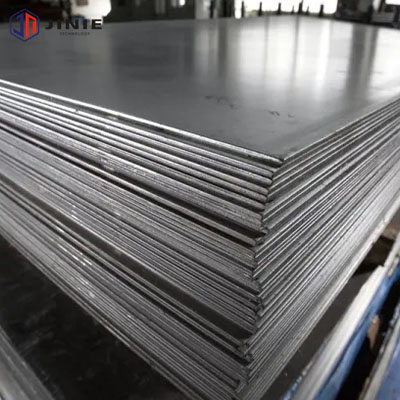

Sheet/Plate | ASTM B435 |  |

Bar /Rod | ASTM B572 |  |

Forging | AMS 5754 GE B50TF31 |  |

Fittings | ASTM B366 |  |

Weld Wire | A5.14 ERNiCrMo-2 |  |

Weld Electrode | A5.11 ENiCrMo-2 |  |

Hastelloy X is widely used in various high temperature environments due to its corrosion resistance in various atmospheres at high temperatures and its excellent high temperature strength.

Industrial and aviation steam turbines (combustors, rectifiers, structural covers).

Industrial furnace components, support rolls, grids, ribbons and radiant tubes.

Spiral tubes in petrochemical furnaces.

High temperature gas cooling nuclear reactor.

Q1: Is Hastelloy X Magnetic?

A: Hastelloy X (UNS N06002) is non-magnetic in the annealed condition. However, cold working may induce slight magnetism from strain-induced martensite. In most cases the magnetism is almost non-existent.

Q2: Is Hastelloy X Precipitation Hardened?

A: No, Hastelloy X is solid-solution strengthened, NOT precipitation hardened.

Q3: Difference Between Inconel 625 vs Hastelloy X

Property | Hastelloy X (UNS N06002) | Inconel 625 (UNS N06625) |

Composition | Ni-Cr-Fe-Mo (+W/Co) | Ni-Cr-Mo-Nb (+Ta) |

Key Strengthening | Solid-solution (Mo/W) | Precipitation (Nb/Ta γ'' phase) |

Max Service Temp | 2200°F (1200°C) | 1800°F (980°C) |

Creep Strength (982°C) | 12,000 psi | 7,000 psi |

Corrosion Focus | Oxidation/sulfidation resistance | Aqueous corrosion (pitting/Cl⁻) |

PREN | ~35 | ~55 |

Primary Applications | Combustors, furnace hardware | Marine, chemical processing |