Views: 61 Author: Rachel Publish Time: 2024-08-02 Origin: Site

Hastelloy X is a nickel-chromium-iron-molybdenum superalloy with outstanding high temperature strength, oxidation resistance, and fabricability. Alloy X maintains excellent oxidation resistance up to 2200°F and also exhibits exceptional resistance to stress corrosion cracking.

The following are similar grades to Hastelloy X alloy in various countries:

Country | Equivalent Grade |

China | GH3536、GH536 |

French | NC22FeD |

Germany | NiCr22Fe18Mo |

America | HastelloyX, UNSN06002, NiCr21Fe18Mo9(ISO) |

JN hastelloy X still shows good ductility after long-term exposure to temperatures of 650°C, 760°C and 870°C for 16,000 hours. The furnace rollers made of it are still in good condition after running for 8,700 hours in a high temperature environment of 1,177°C. It is also easy to process and has good forming, casting and welding properties. It is very suitable for distillation tanks, silencers, furnace baffles, pyrolysis operation pipes and rapid dryer parts in the chemical industry.

JN Alloy is suppliers of Hastelloy X nickel in sheet, pipes, flanges, pipes fittings, round bar, and plate stock in a variety of lengths and widths, and we can custom cut this material to your exact specifications. Our nickel coil can also be slit to your desired width.![]()

Grade | C≤ | Mn≤ | P≤ | S≤ | Si≤ | Cr | Mo | Fe | Co≤ | Ni | W |

Hastelloy X | 0.05-0.15 | 1.0 | 0.04 | 0.03 | 1.0 | 20.5-23.0 | 8.0-10.0 | 17.0-20.0 | 0.5-2.5 | Remainder | 0.2-1.0 |

Product Name | Standard | Show |

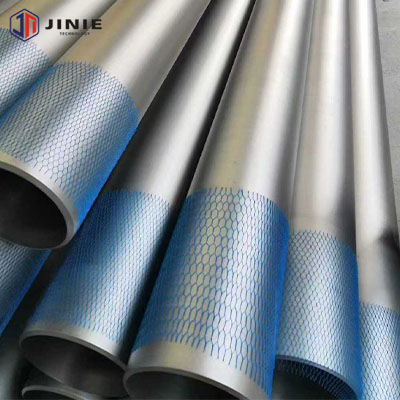

Pipe/Tube | AMS 5587 AMS 5588 ASTM B619 ASTM B622 |  |

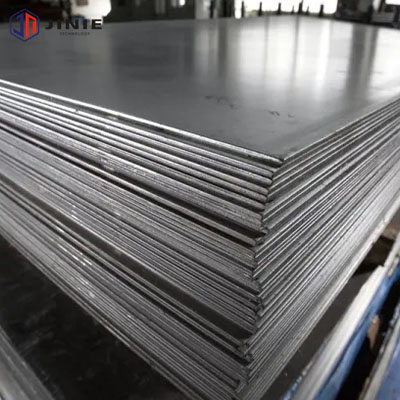

Sheet/Plate | ASTM B435 |  |

Bar /Rod | ASTM B572 |  |

Forging | AMS 5754 GE B50TF31 |  |

Fittings | ASTM B366 |  |

Weld Wire | A5.14 ERNiCrMo-2 |  |

Weld Electrode | A5.11 ENiCrMo-2 |  |

Hastelloy X machining can be performed with conventional methods. Carbide tools are preferred, but high-speed steel cutting tools can also be used. Machinability is similar to that of austenitic stainless steels.

The alloys is tough and, therefore, requires rigid fixturing, low cutting speeds and ample cutting fluids. Additionally, finish grinding is recommended when very close tolerances are required.

UNS N06002 is similar to Inconel 625 and Inconel 718, Hastelloy X has excellent welding ability, particularly in together with GTA, plasma-arc, and electron-beam welding.

Generally, parent metal weld filler is used with welding carried out on solution heat treated material. Often post-weld heat treatment is employed to reduce residual weld shrinkage stresses. Although good in the as-welded condition, weldment strength and ductility are often optimized via full post-weld solution heat treatment or lower temperature stress relief.

Hastelloy X in solution-treated condition demonstrates superior formability, with cold forming compatibility across standard processes including but not limited to: drawing, rolling, bending, spinning, drop hammering, punching, and shearing.

Alloy X possesses excellent corrosion and oxidation resistance. It also has good sea water corrosion resistance and thus attractive for marine applications.

Mills typically supply Alloy X wrought products in solution heat treated condition, providing optimal mechanical properties and corrosion resistance for most applications. X alloy solution heat treatment consists of exposure to 2150 F followed by rapid cooling. The hold time at 2150 F varies with the section size of the product, size of load and furnace characteristics.

When forging Alloy X within the 1750–2150°F range, apply moderate reductions per pass and conduct frequent reheating. For hot upsetting of Hastelloy X, limit the upset length to ≤3× the diameter. Perform impact extrusion near the upper forging temperature limit (2150°F).

Hastelloy X has a wide range of applications in industries that require high-temperature resistance and corrosion resistance. Some of the most common applications of Hastelloy X include:

Gas turbine engines: Hastelloy X is used in gas turbine engines for its ability to withstand high temperatures and corrosive environments.

Industrial furnace components: Hastelloy X is used in the construction of industrial furnaces due to its high-temperature strength and resistance to oxidation and carburization.

Chemical processing equipment: Hastelloy X is used in chemical processing equipment for its resistance to a wide range of corrosive environments.

Aerospace components: Hastelloy X is used in aerospace components such as rocket engine parts and jet engine exhaust components for its high-temperature resistance and mechanical properties.

Is hastelloy x magnetic?

Hastelloy X is typically non-magnetic in its annealed/solution-treated condition, but in cold-worked areas due to localized strain-induced martensite. The following is a comparison of the magnetic properties of Hastelloy X and other alloys in different processing conditions:

| Material | Condition | Magnetic Response |

|---|---|---|

| Hastelloy X | Annealed | Non-magnetic |

| Hastelloy X | Cold-rolled | Slightly magnetic |

| 304 Stainless | Annealed | Non-magnetic |

| 400-series SS | Any condition | Strongly magnetic |

Is hastelloy x precipitation hardnend?

Hastelloy X is NOT a precipitation-hardenable alloy. It achieves its properties solely through solid-solution strengthening and retains a stable austenitic (FCC) crystal structure.

What color is hastelloy x?

Hastelloy X exhibits a metallic silver-gray color in its standard mill finishes, but its appearance varies significantly with surface treatment and oxidation state.