Views: 14 Author: Wang Publish Time: 2025-10-29 Origin: Site

Inconel 718 (UNS N07718) is a nickel-chromium-iron alloy with excellent stability and high strength over the temperature range of -253°C to 700°C.

This alloy exhibits excellent creep resistance and rupture strength at high temperatures, along with good toughness, oxidation resistance, and resistance to stress corrosion cracking. It also exhibits excellent weldability and lacks a tendency to post-weld cracking.

Inconel 718 is available in a wide variety of product forms, including hot-rolled and forged bar, sheet and strip, wire, seamless and welded pipe, forgings, flanges, and fasteners.

Inconel 718 price per kilogram generally increases with the processing.

Product Form Category | Typical Price Range (USD/kg) |

Forging Stock / Billet | 100 - 120 |

Hot-Rolled Bar / Rod | 115 - 140 |

Plate / Sheet | 120 - 150 |

Precision Cold-Drawn Tube | 140 -180 |

Welding Wire / Filler Metal | 150 - 200 |

Additive Manufacturing (AM) Powder | 140 - 260 |

The cost difference of Inconel 718 products lies in their manufacturing process. Prices are usually quoted in kilograms or pounds.

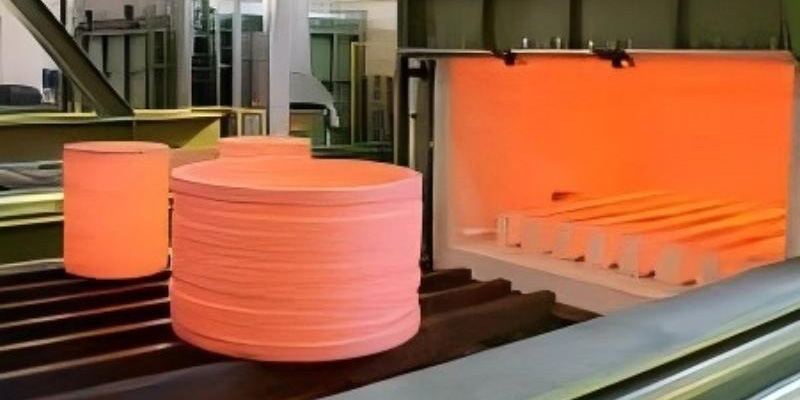

1. Forging Stock / Billets: Large, raw, semi-finished blocks of the alloy. These billets serve as the starting material for smaller shapes or major forgings.

Price Position: Generally the lowest price point per kilogram, as they require the fewest finishing operations and hold the largest volumes.

2. Bar and Rod: Round bars, rods, and occasionally square or hex bars used for machining precision components like bolts, shafts, and fasteners. They are typically supplied in a mill-annealed or age-hardened condition.

Price Position: Mid-range. Prices are higher than billets due to the extensive hot rolling, drawing, or forging required to achieve dimensional tolerance, plus the final heat treatment.

Smaller diameter bars are priced higher than larger diameter bars.

3. Plate and Sheet: Flat products varying in thickness from thin sheets to thick plates.

Price Position: Mid-to-high range.

Plates require hot rolling and flattening processes. Due to thickness tolerances and the additional cold rolling/finishing required per unit weight, the cost per kilogram for thinner sheets is higher.

4. Wire and Welding Consumables: Fine-gauge wire used in spring manufacturing and welding applications.

Price Position: Highest range.

The cost per kilogram is significantly higher due to the specialized high-precision cold drawing process required to reduce the alloy to fine diameters and the strict quality control required for certified welding filler metal.

5. Forgings: Complex shapes, such as turbine disks, blades, or custom flanges, produced via hot or cold forging, and often followed by extensive CNC machining and final heat treatment.

Price Position: Highly variable.

While raw material cost is a factor, price is primarily determined by manufacturing costs, including tooling costs, nondestructive testing, and the work-hardening of the material.

The final price of Inconel 718 is determined by six major factors:

Global Nickel Market

As nickel is the primary composition of Inconel 718, the alloy's price is highly sensitive to the London Metal Exchange Nickel Official Price.

Nickel prices are directly reflected in the cost of 718 alloy, and steel mills usually add a surcharge to the base price of 718 to balance costs.

Alloying Element Costs

Beyond nickel, the price is influenced by other key alloying elements, especially niobium, molybdenum, and cobalt. Niobium, critical for the strengthening phase in Inconel 718, is itself an expensive and often supply-constrained element, contributing a substantial premium over standard nickel alloys.

Melting and Quality Control

Inconel 718 often requires multiple sophisticated melting cycles to achieve ultra-low impurity levels and exceptional chemical homogeneity.

This complex melting process is energy-intensive and time-consuming, adding significant cost to the base material compared to standard air-melted or single-melt alloys.

Dimension and Surface Tolerance

The amount of work-hardening that Inconel 718 undergoes during formation. Products requiring high precision (e.g., cold-drawn bars with H9 tolerance, precision-rolled foil) must undergo slow, multi-stage processing with frequent inter-process annealing.

The higher the dimensional and surface finish requirement, the higher the ultimate cost per unit.

Heat Treatment and Certification

Inconel 718 is typically sold in the solution-annealed or fully age-hardened state. The final age-hardening treatment is essential to achieve its peak mechanical properties, and this treatment adds a specific cost.

Furthermore, certification for critical applications (e.g., aerospace or nuclear) requires extensive nondestructive testing and comprehensive mill test certificates to standards, which includes the cost of testing labor and documentation.

Order Quantity and Lead Time

Like all specialty metals, Inconel 718 operates on a tiered pricing structure. Large volume orders directly from the mill generally secure the lowest prices.

Smaller quantities or requirements for fast delivery will incur additional costs for inventory holding, cutting, and handling.

Custom sizes or non-stock grades can face significantly extended lead times and a corresponding price premium.

The Inconel 718 procurement specialists must understand that the final price is a function of the nickel price multiplied by the complexity factor of the desired product form.

For accurate budgeting, always obtain a formal quote that clearly delineates the base alloy price, the alloy surcharge, and the manufacturing premium based on the required dimensions and certification.

Need to get online inconel 718 product prices?