Views: 3 Author: Monica Publish Time: 2026-01-16 Origin: Site

In December 2025, JN Company received an inquiry from an Argentine offshore platform procurement officer. Argentina requires a large quantity of WN flanges resistant to seawater and hydrogen sulfide rings for oil and gas development, primarily for transporting oil and natural gas containing corrosive substances.

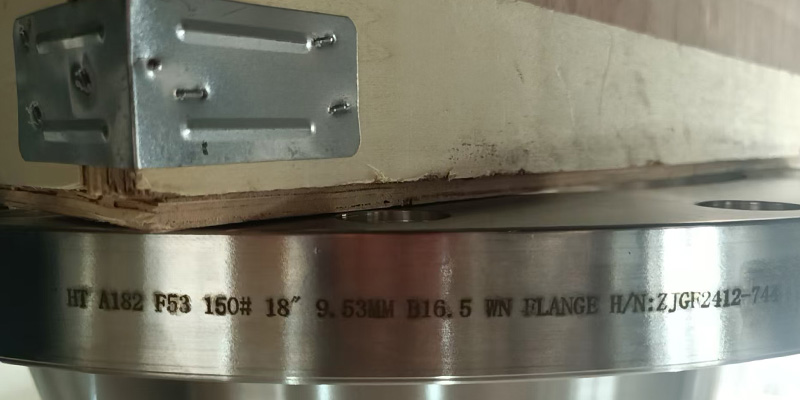

F53 (UNS S32750 Super Duplex Stainless Steel) is a critical piping component for connecting pipelines carrying highly corrosive media, such as seawater desalination, chemical transportation, and equipment, exhibiting excellent resistance to chloride stress corrosion cracking, pitting corrosion, and crevice corrosion.

Weld neck flange, also known as a welding neck flange, high-hub flange, or tapered hub flange. It consists of a circular disk with a protruding rim around the circumference, featuring a series of drilled holes for bolting to another flange or component. The defining characteristic is its long, tapered hub (or neck), which gradually transitions to match the pipe's wall thickness, allowing for a butt weld connection.

Grade | F53/UNS S32750 | |

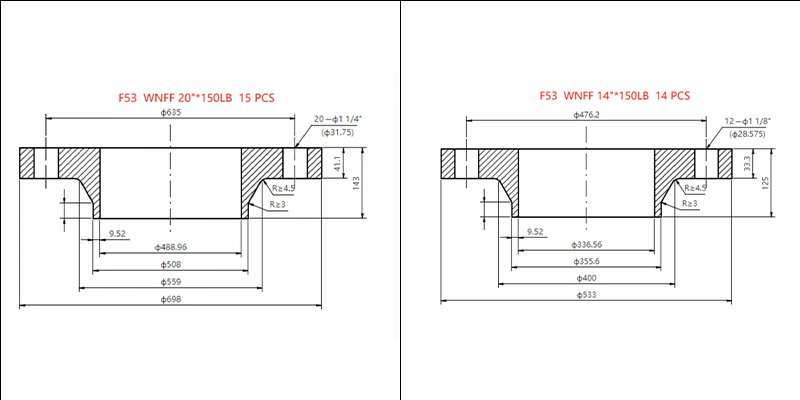

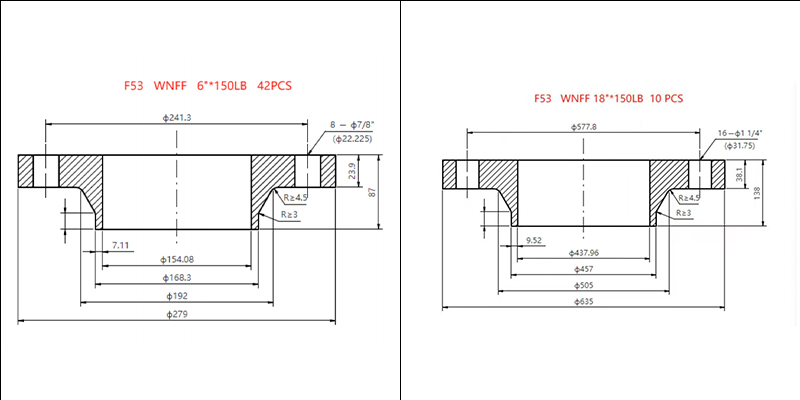

WN Flanges | 14 inch 150FF | 69 PCS |

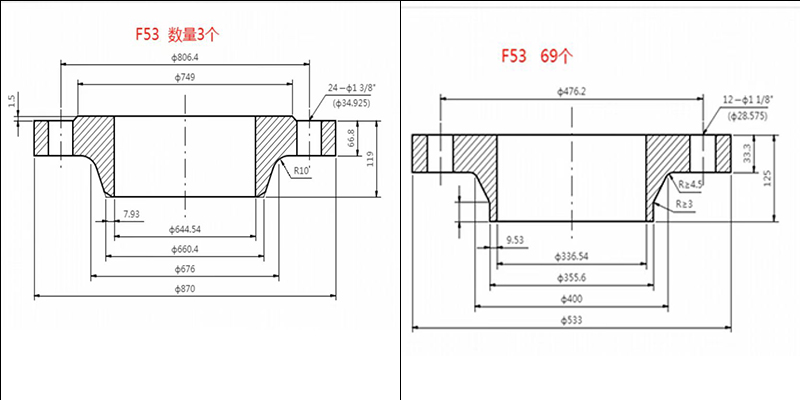

26 inch 150 RF | 3 PCS | |

18 inch 150LB | 10 PCS | |

FF 6 inch 150LB | 42 PCS | |

FF 20 inch 150LB | 15 PCS | |

FF 14 inch 150LB | 14 PCS | |

We are pleased to announce the successful delivery of 153 pieces of F53 (UNS S32750) Weld Neck (WN) Flanges to a valued partner in Argentina’s energy sector. This order shows the global trust in our product quality and expertise. Our Argentinian customer selected our products for several reasons.

1. Certification and Traceability Guarantee Absolute Compliance.

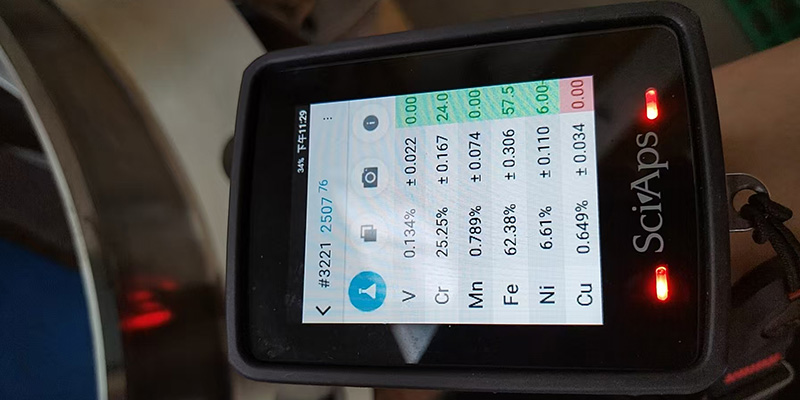

Our F53 flanges are supplied with full material certification (including 3.1 mill certificates), and strict heat-code traceability, meeting the stringent requirements of international oil & gas and chemical projects, which was a fundamental prerequisite for our customer’s operational safety and audit compliance.

2. Superior Material Performance Ensures Long-Term Reliability.

The duplex stainless steel F53 (S32750) offers exceptional corrosion resistance and high strength, particularly suited for offshore and high-pressure, chloride-rich environments. Our customer required flanges that could guarantee decades of service without failure, minimizing lifecycle costs.

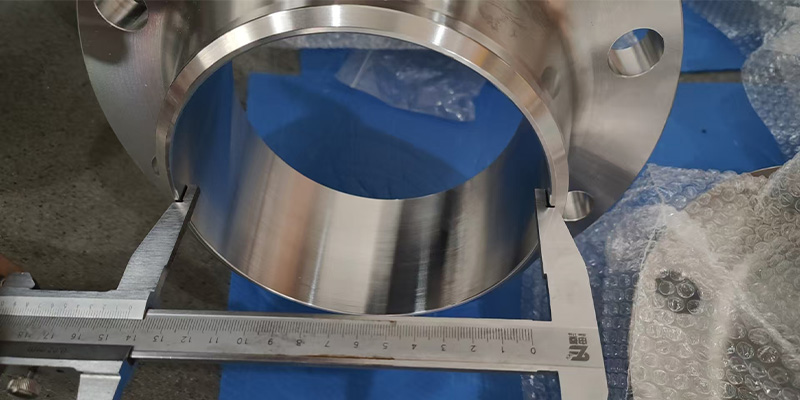

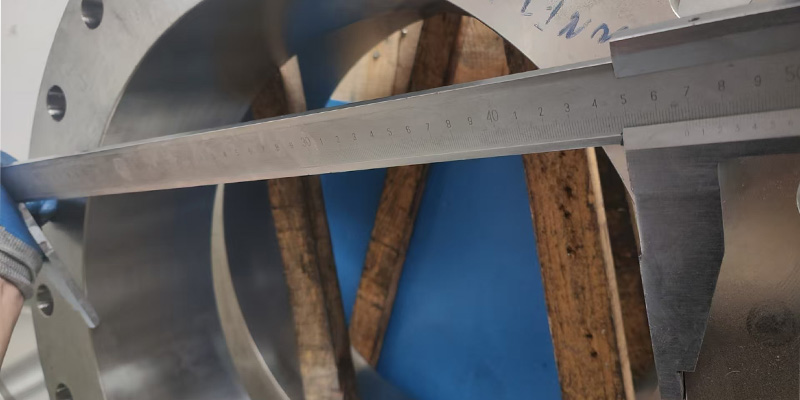

3. Precision Manufacturing Delivers Perfect Fit and System Integrity.

Every flange is manufactured to ASME/ANSI B16.5 and other relevant standards with CNC precision, ensuring perfect dimensional accuracy, surface finish, and bore alignment.

4. Competitive Cost-Efficiency with Quality.

By integrating advanced manufacturing processes with stringent in-house quality control, we provide industry-leading flanges that offer a superior cost-performance ratio. Our customer recognized that our products deliver premium quality without premium markup, ensuring project viability.

This partnership with Argentina reinforces our commitment to supporting global needs with reliable, certified, and high-performance piping components. We are your trusted partner for specialized flange solutions.

Contact us today to discuss your project requirements.