Views: 3 Author: Monica Publish Time: 2025-12-12 Origin: Site

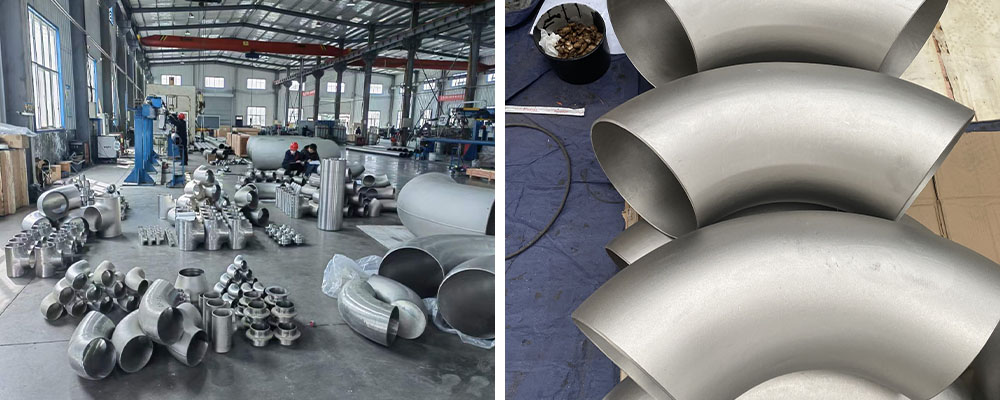

JN sold 9 UNs of ASME B16.9 WP316/316L stainless steel long radius 90-degree elbows to a Turkish customer.

Our Long Radius 90-degree Elbows strictly adhere to ASME B16.9 standards. All elbows are manufactured entirely seamlessly using ASTM A403 WP316 material and undergo solution heat treatment and pickling passivation to ensure superior corrosion resistance, consistent wall thickness, and smooth inner wall finish.

QTT. | UNIT. | DESCRIPTION |

1,00 | UN | 90 DEG ELBOW, LONG RADIUS, WELDED, STAINLESS STEEL, ASTM A403 GR. WP316/316L, ASME B16.9, BEVELED ENDS, 12 INCH X S-80S |

3,00 | UN | 90 DEG ELBOW, LONG RADIUS, WELDED, STAINLESS STEEL, ASTM A403 GR. WP316/316L, ASME B16.9, BEVELED ENDS, 16 INCH X XS |

1,00 | UN | 90 DEG ELBOW, LONG RADIUS, WELDED, STAINLESS STEEL, ASTM A403 GR. WP316/316L, ASME B16.9, BEVELED ENDS, 18 INCH X XS |

3,00 | UN | 90 DEG ELBOW, LONG RADIUS, WELDED, STAINLESS STEEL, ASTM A403 GR. WP316/316L, ASME B16.9, BEVELED ENDS, 20 INCH X XS |

1,00 | UN | 90 DEG ELBOW, LONG RADIUS, WELDED, STAINLESS STEEL, ASTM A403 GR. WP316/316L, ASME B16.9, BEVELED ENDS, 8 INCH X S-40S |

As a specialized stainless steel fitting supplier with over 20 years of focus on 316/316L piping components, we manufacture our Long Radius 90° Elbows exclusively from mill-certified, low-carbon 316/316L material sourced from reputable steel mills. Every heat lot is accompanied by original EN 10204 3.1 certificates verifying chemical composition, mechanical properties, and full traceability.

Our Long Radius (1.5D) reduces pressure drop and turbulence compared to short-radius elbows, typically lowering frictional losses by 30–40% at the same flow rate while minimizing erosion-corrosion at the extrados. Precision butt-weld ends are machined to ASME B16.9 dimensional tolerances with bevel angles maintained at 37.5° ± 2.5° and root faces of 1.6 mm ± 0.8 mm, ensuring perfect orbital welding alignment and full penetration without burn-through.

Quality is verified through a rigorous in-house protocol that exceeds industry norms: 100% positive material identification (PMI), 2.5% Mo verification), 100% dimensional inspection, and 100% hydrostatic or pneumatic pressure testing on request. Third-party inspection is welcomed at any step.

When you specify our 316/316L Long Radius 90° Elbows, you receive components engineered for maximum service life, regulatory compliance.

Stock availability from ½″ through 24″ in Sch 10S/40S/80S, same-day technical documentation, and competitive lead times—supported by a no-quibble 24-month warranty—make us the reliable single-source partner for your critical stainless steel piping systems.

Welcome to inquire about 316 stainless steel pipe fittings!