Views: 1 Author: Monica Publish Time: 2025-12-22 Origin: Site

This blog will introduce the technical specifics of the ASME B16.9 180° Short Radius Elbow, providing the clarity needed for specification and procurement.

An ASME B16.9 180° Short Radius Elbow, often called a "return bend" or "U-bend," is a buttwelding pipe fitting that changes the direction of a pipeline by 180 degrees. Its characteristic is compactness: the center-to-center distance is equal to twice the nominal pipe size (2 x NPS), or more fundamentally, its bending radius (R) is equal to the nominal pipe diameter (1D).

This is in contrast to a Long Radius (LR) 180° elbow, which has a bending radius of 1.5 times the nominal pipe size. The compact shape of the SR elbow makes it the ideal choice for space-constrained installations, such as in skid-mounted units, heat exchanger banks, or tight equipment layouts.

Advantages include:

Butt-weld Connection: Ensures a strong, leak-proof joint when welded to pipes.

Seamless or Welded Construction: Available in seamless forms for smaller sizes and welded for larger diameters to maintain structural integrity.

Pressure Ratings: Compatible with various schedules like SCH 10, SCH 40, and SCH 80, aligning with system requirements.

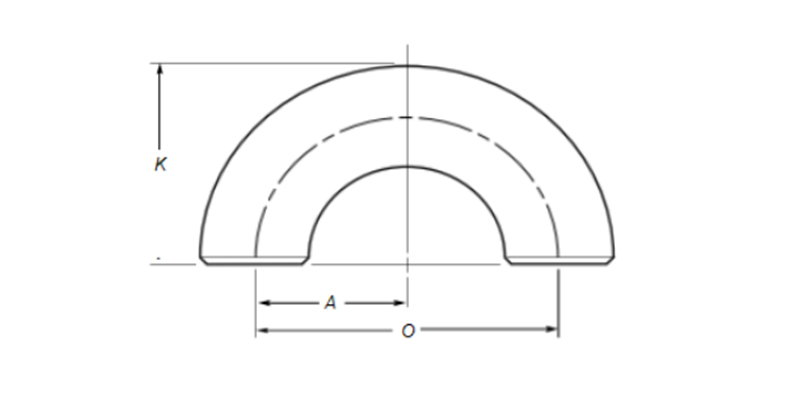

ASME B16.9 specification provides precise measurements for Short Radius 180° Returns, covering Nominal Pipe Sizes (NPS) from 1" to 24".

Below is a comprehensive table outlining the key dimensions: Outside Diameter at Bevel (OD), Center-to-Center (O), and Back-to-Face (K). All values are presented in both millimeters (mm) and inches (in.) for universal applicability.

Nominal Pipe Size (NPS) | Outside Diameter at Bevel (OD) | Center-to-Center (O) | Back-to-Face (K) |

mm in. | mm in. | mm in. | |

1 | 33.4 1.32 | 51 2.00 | 41 1.62 |

1 1/4 | 42.2 1.66 | 64 2.50 | 52 2.06 |

1 1/2 | 48.3 1.90 | 76 3.00 | 62 2.44 |

2 | 60.3 2.38 | 102 4.00 | 81 3.19 |

2 1/2 | 73.0 2.88 | 127 5.00 | 100 3.94 |

3 | 88.9 3.50 | 152 6.00 | 121 4.75 |

3 1/2 | 101.6 4.00 | 178 7.00 | 140 5.50 |

4 | 114.3 4.50 | 203 8.00 | 159 6.25 |

5 | 141.3 5.56 | 254 10.00 | 197 7.75 |

6 | 168.3 6.62 | 305 12.00 | 237 9.31 |

8 | 219.1 8.62 | 406 16.00 | 313 12.31 |

10 | 273.0 10.75 | 508 20.00 | 391 15.38 |

12 | 323.8 12.75 | 610 24.00 | 467 18.38 |

14 | 355.6 14.00 | 711 28.00 | 533 21.00 |

16 | 406.4 16.00 | 813 32.00 | 610 24.00 |

18 | 457.0 18.00 | 914 36.00 | 686 27.00 |

20 | 508.0 20.00 | 1016 40.00 | 762 30.00 |

22 | 559.0 22.00 | 1118 44.00 | 838 33.00 |

24 | 610.0 24.00 | 1219 48.00 | 914 36.00 |

These dimensions adhere to the tolerances specified in ASME B16.9, which include allowances for ovality, wall thinning, and alignment.

It's worth noting that for sizes beyond 24" NPS, custom fabrication may be required, often referencing ASME B16.28 or MSS-SP-43 standards for extended compatibility.

ASME B16.9 standard stipulates strict dimensional tolerances to ensure fit-up and weld quality. These tolerances vary based on the NPS of the fitting.

Table: Dimensional Tolerances for ASME B16.9 180° Elbows

NPS Range | Outside Diameter at Bevel (D) | Center-to-Center (O) | Back-to-Face (K) |

1/2 to 2 1/2 | +1.6 mm / -0.8 mm | ±6 mm | ±6 mm |

3 to 3 1/2 | ±1.6 mm | ±6 mm | ±6 mm |

4 | ±1.6 mm | ±6 mm | ±6 mm |

5 to 8 | +2.4 mm / -1.6 mm | ±6 mm | ±6 mm |

10 to 18 | +4.0 mm / -3.2 mm | ±10 mm | ±6 mm |

20 to 24 | +6.4 mm / -4.8 mm | ±10 mm | ±6 mm |

Furthermore, the standard mandates that the wall thickness at any point shall not be less than 87.5% of the specified nominal wall thickness.

Common Materials: These elbows are manufactured in a wide array of materials to suit service conditions.

Stainless Steels: ASTM A403 WP304/304L, WP316/316L, WP321, and duplex/super duplex grades S31803, S32750 for excellent corrosion resistance.

Nickel Alloys: Alloy 200/201, Alloy 400, Alloy 600, Alloy 625, and Alloy C-276 for severe corrosive and high-temperature environments.

Carbon & Low-Alloy Steels: ASTM A234 WPB, WPC for general service, and A420 WPL6 for low-temperature applications.

Manufacturing Processes: The two primary methods are seamless hot induction or push bending and welded from plate or pipe segments. Seamless fittings are generally preferred for critical service involving high pressure, temperature, or corrosion.

Wall Thickness Schedule: Fittings are available in standard pipe schedule wall thicknesses or to match specific nominal wall dimensions. The schedule must be specified to match the connecting pipe and meet the design pressure requirements.

The Short Radius 180° Elbow suits in applications where space is at a premium and a full reversal of flow is required.

Typical Industries and Uses:

Chemical & Petrochemical Plants: In heat exchanger piping, pump suction and discharge loops, and compact reactor feed systems.

Power Generation: For boiler feedwater systems, fuel oil lines, and instrument tubing within tight confines.

Shipbuilding & Offshore: Where engine room and platform space is severely limited, making compact piping runs essential.

Pulp & Paper and General Manufacturing: In equipment skids and modules that are pre-fabricated for easy installation.

At Jinie, we offer a wide range of Short Radius 180° Return Bends in various stainless steel and nickel alloy materials. For any inquiries, custom orders, or technical assistance, please contact our team of experts today.